Air chushion belt conveyor advantages

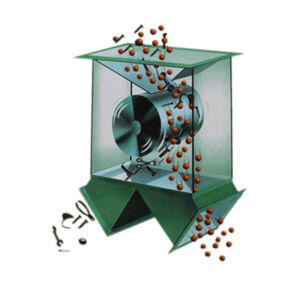

- The air cushion belt conveyor is composed of head and tail rollers, round-trip air chamber, blower system, dust collection system, multi-stage cleaning system and tensioning device.

- Cost saving: no truss, no corridor, Y-shaped leg design.

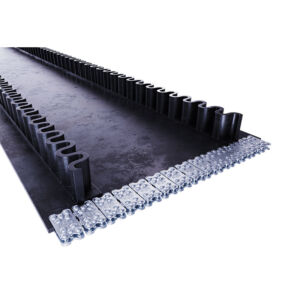

- Energy saving: The whole air cushion has no idlers, saving energy consumption of the system.

- Maintenance-free: The main conveyor section is maintenance-free (no moving parts).

- Large conveying capacity: maximum conveying capacity 1200m3/h, maximum inclination angle 18°.

- Fully sealed structure: dust-free, environmentally friendly

- Stable and reliable: Self-cleaning device to eliminate material accumulation and blockage.

Air Cushion Belt Conveyor Description

The air cushion belt conveyor adopts a unique air cushion structure for both the bearing (material) layer and the return (no-load) layer, which is ideal for long-distance transportation of bulk materials