Heavy-Duty Idlers for Conveyor Material Selection:

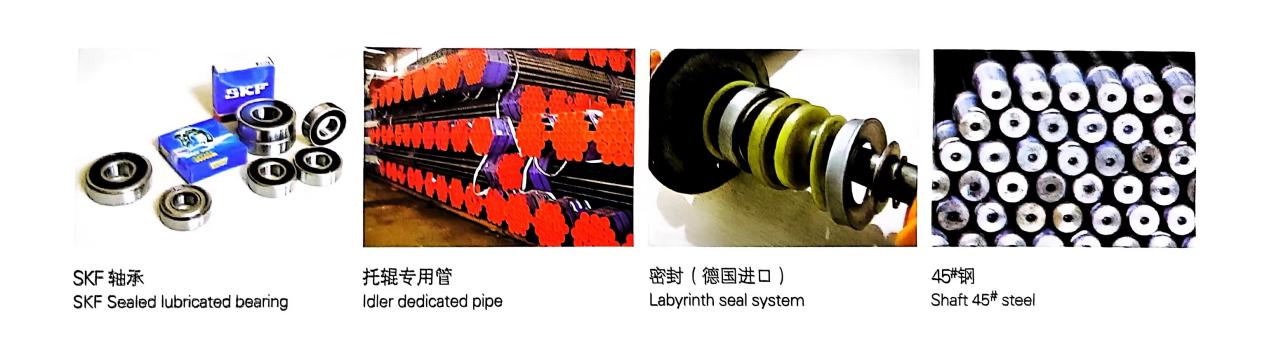

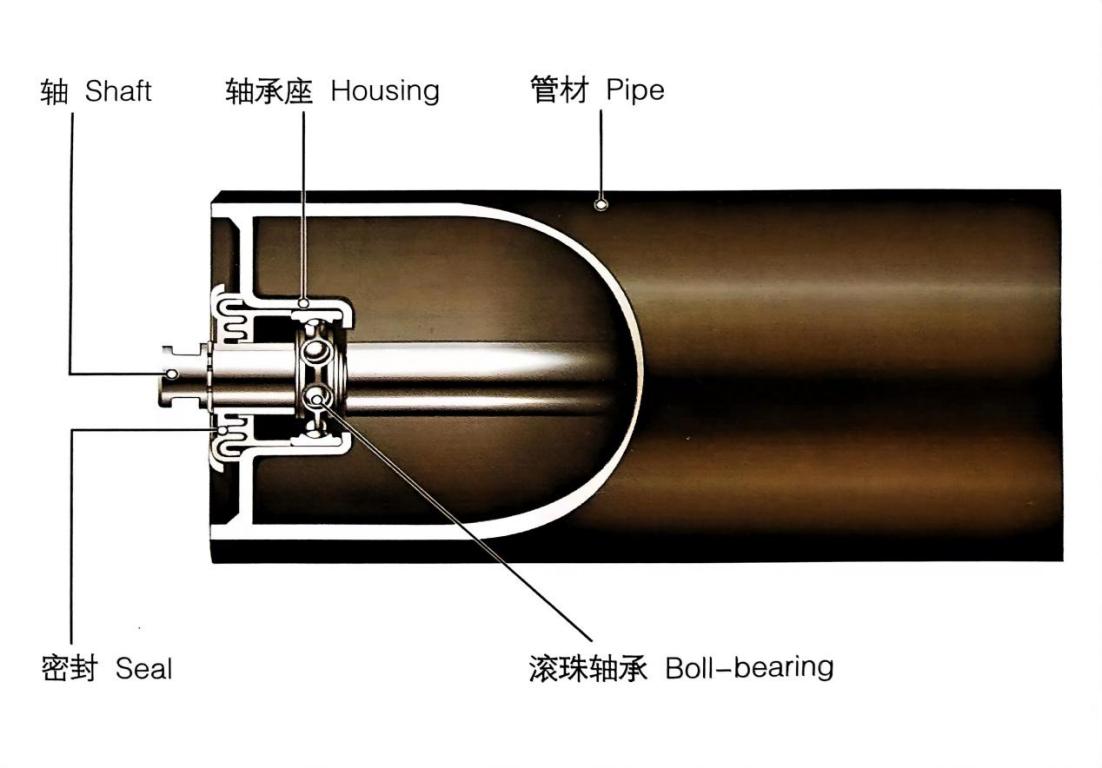

The idler produced by Guangxing is a fully sealed waterproof and dustproof type bracket, and the raw materials are selected from the special pipe for idler, Tongling Sanjia bearing seat, human-oriented bearing, and German imported sealing ring, which has the characteristics of high precision, long life and reliable performance

Heavy-Duty Idlers for Conveyor Roller Specifications

| Roller Specifications | |||

| Standard diameter | length range | Idler’s pipc thickness | Bearing Type |

| mm | mm | mm | min-max |

| 63.5 | 150-3500 | 3.0-3.75 | 204 |

| 76 | 150-3500 | 3.0-4.0 | 204 205 |

| 89 | 150-3500 | 3.0-4.0 | 204 205 |

| 102 | 150-3500 | 3.5-4.0 | 204 205 305 |

| 108 | 150-3500 | 3.5-4.0 | 204 205 305 306 |

| 114 | 150-3500 | 3.5-4.5 | 205 206 305 306 |

| 127 | 150-3500 | 3.5-4.5 | 204 205 305 306 |

| 133 | 150-3500 | 3.5-4.5 | 205 206 207 305 306 |

| 140 | 150-3500 | 3.5-4.5 | 205 206 207 305 306 |

| 152 | 150-3500 | 4.0-4.5 | 205 206 207 305 306 307 308 |

| 159 | 150-3500 | 4.0-4.5 | 205 206 207 305 306 307 308 |

| 165 | 150-3500 | 4.5-6.0 | 207 305 306 307 308 |

| 177.8 | 150-3500 | 4.5-6.0 | 207 306 307 308 309 |

| 190.7 | 150-3500 | 4.5-6.0 | 207 306 307 308 309 |

| 194 | 150-3500 | 4.5-6.0 | 207 307 308 309 310 |

| 219 | 150-3500 | 4.5-6.0 | 308 309 310 |

Heavy-Duty Idlers for Conveyor Advantages

- Sturdy housing, reinforced wall thickness and unique roller structure

- The structure is tightened, the load-bearing capacity is strong, and the rotational resistance is effectively reduced.

- The double labyrinth seal construction is suitable for extremely harsh environments.

- Compared with traditional painting, the high-temperature coating process not only has a beautiful surface, but also improves the wear resistance and weather resistance by 4-5 times.

Heavy-Duty Idlers for Conveyor DESCRIPTION

This idler is a heavy-duty idler specially designed for high-volume, heavy-load, high-speed applications. The unique design allows us to meet the requirements of large-scale open-pit coal mines and metal mines with a transportation capacity of up to 9000t/h-25000t/h, and the reasonable structure and process ensure that the radial runout is minimal, the axial load is maximized, and the dynamic balance reaches a higher grade, minimizing vibration while reducing noise and energy consumption.