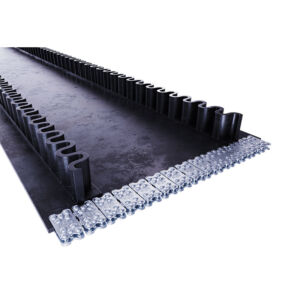

High-Precision Ground Ceramic Idlers for conveyor Material selection:

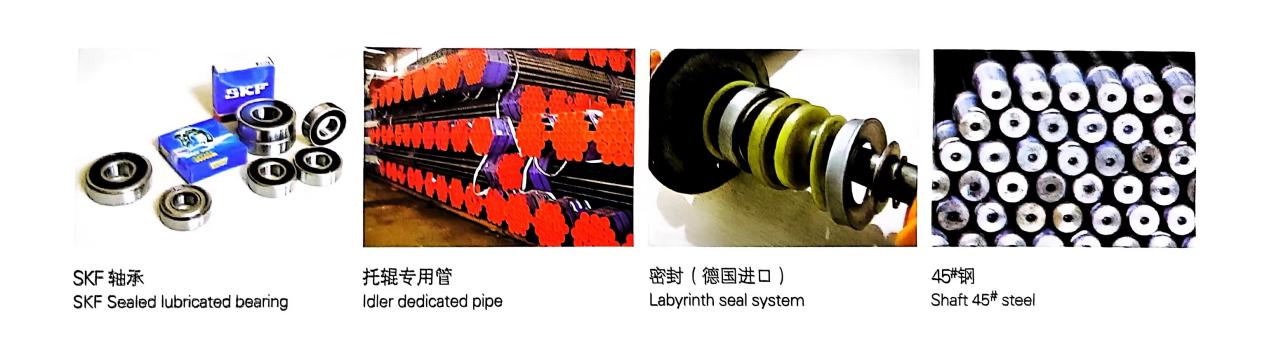

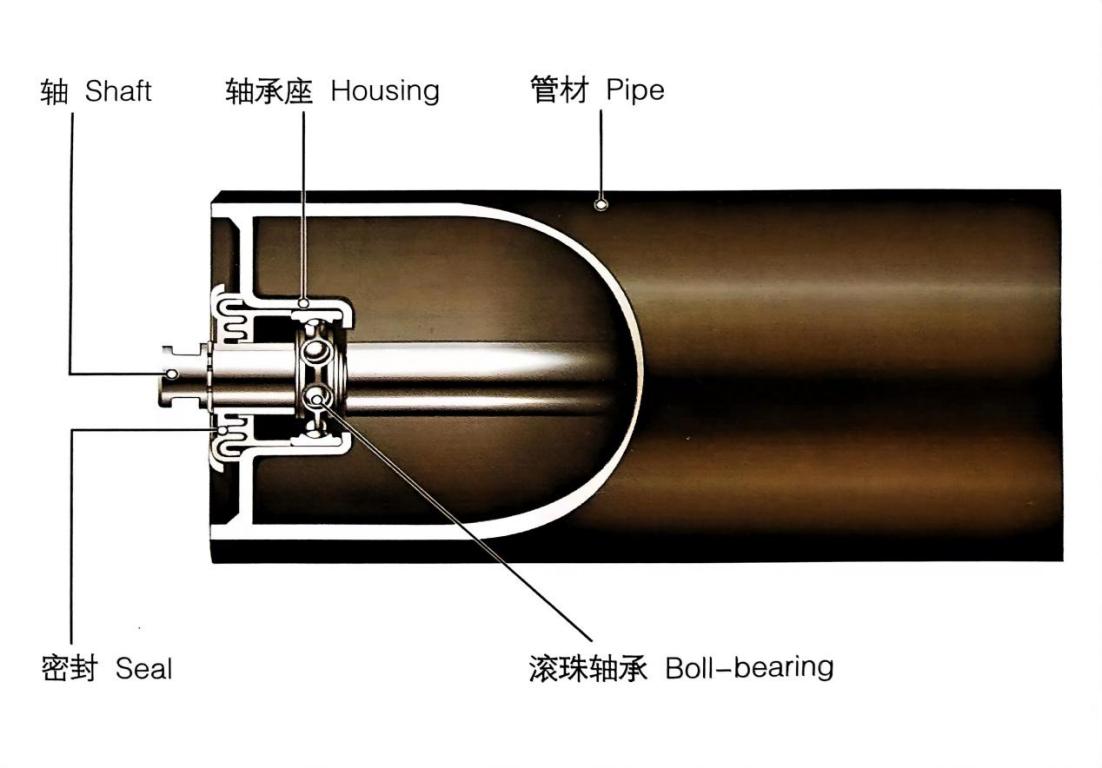

The idler produced by Guangxing is a fully sealed waterproof and dustproof type bracket, and the raw materials are selected from the special pipe for idler, Tongling Sanjia bearing seat, human-oriented bearing, and German imported sealing ring, which has the characteristics of high precision, long life and reliable performance

| Roller Specifications | |||

| Standard diameter | length range | Idler’s pipc thickness | Bearing Type |

| mm | mm | mm | min-max |

| 63.5 | 150-3500 | 3.0-3.75 | 204 |

| 76 | 150-3500 | 3.0-4.0 | 204 205 |

| 89 | 150-3500 | 3.0-4.0 | 204 205 |

| 102 | 150-3500 | 3.5-4.0 | 204 205 305 |

| 108 | 150-3500 | 3.5-4.0 | 204 205 305 306 |

| 114 | 150-3500 | 3.5-4.5 | 205 206 305 306 |

| 127 | 150-3500 | 3.5-4.5 | 204 205 305 306 |

| 133 | 150-3500 | 3.5-4.5 | 205 206 207 305 306 |

| 140 | 150-3500 | 3.5-4.5 | 205 206 207 305 306 |

| 152 | 150-3500 | 4.0-4.5 | 205 206 207 305 306 307 308 |

| 159 | 150-3500 | 4.0-4.5 | 205 206 207 305 306 307 308 |

| 165 | 150-3500 | 4.5-6.0 | 207 305 306 307 308 |

| 177.8 | 150-3500 | 4.5-6.0 | 207 306 307 308 309 |

| 190.7 | 150-3500 | 4.5-6.0 | 207 306 307 308 309 |

| 194 | 150-3500 | 4.5-6.0 | 207 307 308 309 310 |

| 219 | 150-3500 | 4.5-6.0 | 308 309 310 |

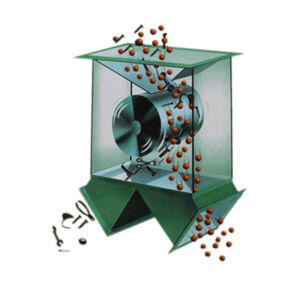

High-Precision Ground Ceramic Idlers for conveyor Advantages

- Never rust, resistant to acid, alkali, salt and other chemical media corrosion.

- High strength, low resistance, good wear resistance.

- The surface of the ceramic forms an oxide film, which does not stick to any substance, and no substance reacts.

- Long service life and extended belt life.

High-Precision Ground Ceramic Idlers for conveyor DESCRIPTION

The high-precision grinding ceramic tray developed by our company is suitable for all kinds of harsh environments, not only wear-resistant, acid and alkali salt, anti-oxidation, stable operation, but also can effectively prevent belt misalignment and reduce belt wear. In the harsh high temperature environment, the service life of ordinary idlers is more than doubled, reducing the manpower, material resources and time wasted by frequent replacement of pallets, reducing operating costs and improving work efficiency.