TD75 Belt Conveyor RANGE:

TD75 type universal fixed belt conveyor (hereinafter referred to as TD type) is widely used to transport bulk materials or finished items in metallurgy, coal, transportation, hydropower and other departments due to the advantages of large conveying capacity, simple structure, convenient maintenance, low cost and strong versatility. According to the requirements of the conveying process, it can be conveyed by a single machine, or multiple or other conveyors can form a horizontal or inclined conveying system. The TD75 type is used in the range of ambient temperature +40C to -10C, and the temperature of the conveyed material is below 50C. For occasions with special requirements such as explosion-proof, waterproof, anti-corrosion, heat resistance, and cold resistance, corresponding measures should be taken separately.

TD75 Belt Conveyor STRUCTURAL FEATURES:

Whole machine layout:

The whole machine layout of TD75 type should be selected by the designer according to the material conveying process and its requirements after the main parameter selection and some calculations, and select the various components of this series to form a complete conveyor. Generally, the whole machine is arranged with the following basic forms of conveyor belts

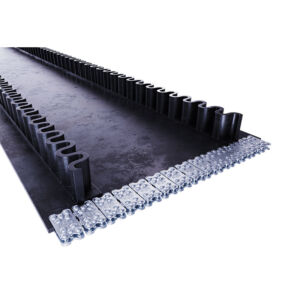

It is the main component of electric guidance and bearing materials. TD75 type adopts two types: ordinary rubber conveyor belt and plastic conveyor belt. The joints of the conveyor belt can be connected by mechanical clips or sulfur (plasticized). When using an instrument card connection, the belt strength will be used in depreciation due to the reduction of joint strength, which is especially noticeable for the whole core plastic tape. Therefore, the mechanical card connection is suitable for short conveyors or occasions where the maintenance time is particularly short, the use of sulfur (plastic) connection can greatly extend the service life of the conveyor belt, and its joint strength is slightly lower than the XD body strength of the conveyor belt.

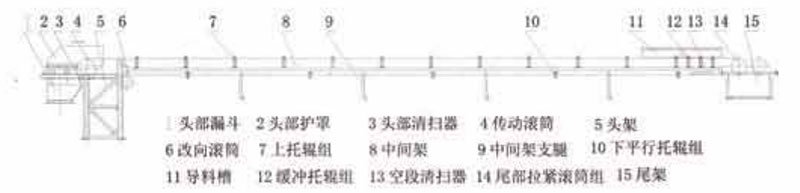

TD75 Belt Conveyor OVERALLINSTALLATION DIAGRAM:

TD75 Belt Conveyor TECHNICALPARAMETERS:

| Carrier support Roll form |

With speed (m/s) | Bandwidth B (mm) | |||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | ||

| Conveying capacity Q(m/h) | |||||||

| Trough idlers | 0.8 | 78 | 131 | ||||

| 1.0 | 97 | 164 | 278 | 435 | 655 | 891 | |

| L.25 | 122 | 206 | 348 | 544 | 819 | 1115 | |

| 1.6 | 156 | 264 | 445 | 696 | 1048 | 1427 | |

| 2.0 | 191 | 323 | 546 | 853 | 1284 | 1748 | |

| 2.5 | 232 | 391 | 661 | 1033 | 1556 | 2118 | |

| 3.15 | 824 | 1233 | 1858 | 2528 | |||

| 4.0 | 2202 | 2996 | |||||

| Parallel idlers | 0.8 | 41 | 67 | 118 | |||

| 1.0 | 52 | 88 | 147 | 230 | 345 | ||

| 1.25 | 66 | 110 | 184 | 288 | 432 | 469 | |

| 1.6 | 84 | 142 | 236 | 368 | 558 | 588 | |

| 2.0 | 103 | 174 | 289 | 451 | 677 | 922 | |

| 2.5 | 125 | 211 | 350 | 546 | 821 | 1117 | |

TD75 Belt Conveyor Description

TD75 belt conveyor has become a kind of mass conveyor due to its simple structure, low cost, strong component versatility and convenient maintenance. Depending on the requirements, horizontal or inclined conveyor systems can be formed individually, multiple or with other conveying equipment.