Desulphurization:

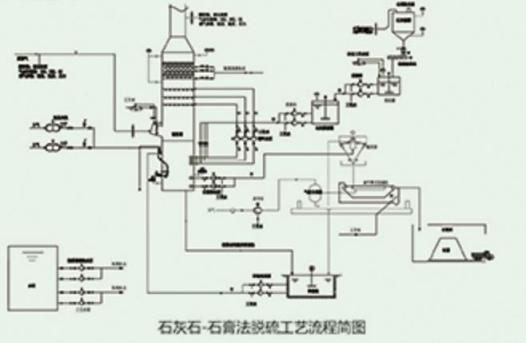

I 、Flue gas wet desulfurization process (limestone one-stone breeding method)

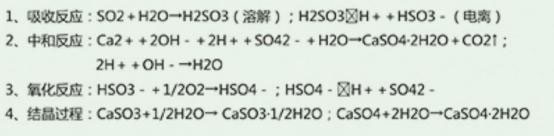

Introduction: Limestone – gypsum wet desulphurization process has long occupied the mainstream market of flue gas desulphurization at home and abroad, accounting for about 90% of the total installed desulphurization machine. This process takes cheap lime powder, or limestone powder as desulphurization agent to absorb and remove SO2 in the flue gas. After the reaction, calcium sulfate (gypsum) and other products are dehydrated, and waste liquid is

recycled. The stone enters other sections for in-depth treatment and recycling.

Reaction principle:

Technical advantage

1, high absorption efficiency, can reach more than 98%

2, raw materials, large output, low price

3, mature process, stable operation

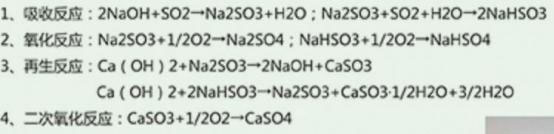

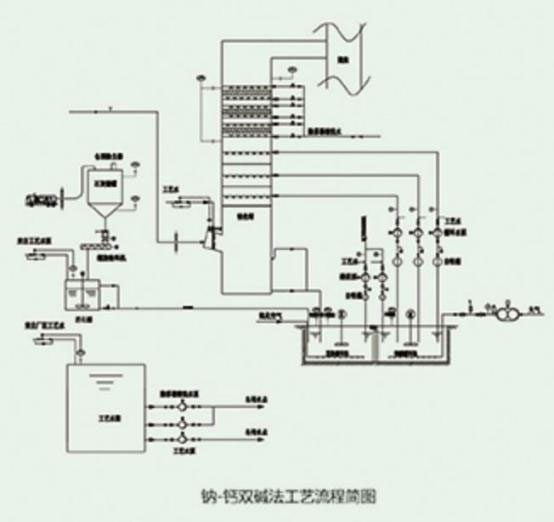

Two, flue gas wet desulfurization process (sodium calcium double alkali method)

About:

Sodium carbonate or sodium ammoxide solution is the first alkali to absorb S02 in the flue gas, and then lime or hydrated lime as the second base, treatment of the absorption liquid, the regenerated absorption liquid is returned to the absorption tower for recycling, because different types of alkali are used in the absorption and absorption liquid treatment, it is called the double alkali method.

Reaction principle:

Technical advantage

1, the reaction rate is fast, the efficiency is high, the absorption is complete

2, the normal operation pipeline is not easy to plug

3, less construction investment

4, low liquid-gas ratio, low power consumption.

5, high absorption efficiency, can reach more than 98%

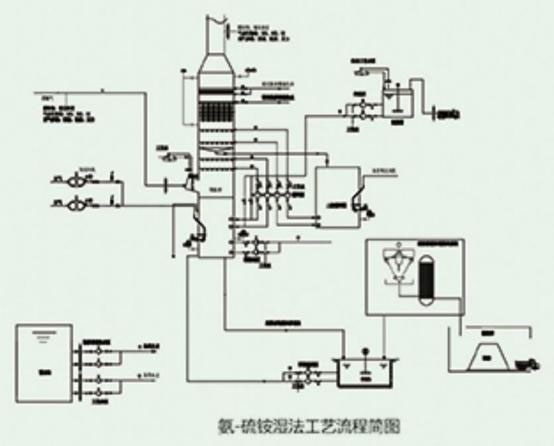

Fluegas wet desulfurization process (ammonia method)

Introduction:

Although the process of ammonia desulphurization started late, it has also tended to mature. Compared with limestone-gypsum desulfurization process, ammonia desulfurization can be easier to achieve more than 98% desulfurization efficiency, and can share ammonia supply system with SCR and other denitrification processes, and by-product sulfuric acid is relatively high value, economic benefits are obvious, many times by the Ministry of Environmental Protection and other departments proved to be “a green process in line with the national low-carbon circular economy”. The use of amino absorbent to absorb SO2 in the flue gas to generate sulfite (hydrogen), and under the condition of oxygen enrichment, the sulfite (hydrogen) is oxidized into sulfuric acid, and then the flue gas heat concentration, supersaturated product precipitation (NH4)2S04 solid, filtered and dried to get fertilizer products.

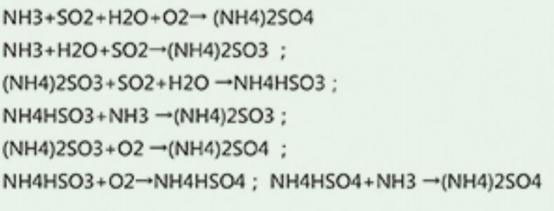

Reaction principle:

Technical advantage

1, by-product sulfuric acid is more recyclable

2, low energy consumption, low operating cost

3, high absorption efficiency, can reach more than 98%

4, suitable for chemical enterprises with ammonia source

Flue gas wet desulfurization process (magnesium oxide method)

About:

Magnesium oxide wet desulphurization process is similar to lime gypsum desulphurization process. It is an advanced, efficient and economical desulphurization system which takes magnesium oxide (Mgo) as raw material and produces magnesium hydroxide (Mg(OH)2) as desulphurization agent. The oxidation in the flue gas reacts with the iron hydroxide in the spray slurry to be removed. The final reaction product is a mixture of ferric sulfite and ferric sulfate.

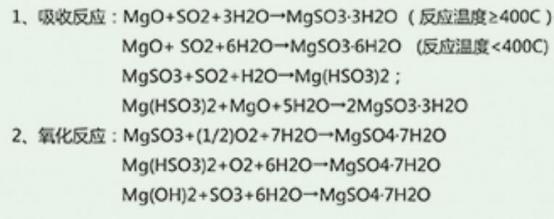

Reaction principle:

Technical advantage

1 、Liquid gas ratio is relatively low 2, sufficient raw materials, easy to buy 3, relatively less investment 4, low power consumption, save operating costs 5, high absorption efficiency, can reach more than 98% 6, good availability of agents, relatively high reactivity, high desulfurization efficiency

Five, flue gas wet desulfurization process (sodium-alkali: method)

Introduction:

Sodium alkali method flue gas desulfurization technology, gas in contact with lye, sulfur dioxide will react with lye, so as to achieve the effect of removing sulfur dioxide. Sodium breakdown decomposition is large, high activity, strong reaction capacity, high desulfurization efficiency. It is

not easy to form scale and blockage in desulphurization tower and pipeline

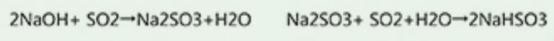

Reaction principle:

Technical advantage

1, the process is simple, covers less land, easy to operate

2, less construction investment, high absorption efficiency

3, the solubility is high, the pipeline is not blocked cold phenomenon, the reaction tower ginger precipitation, less scaling

4, the absorption effect is high, can reach more than 98%

Denitration:

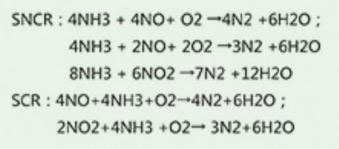

FlueGas Denitrification process (SNCA)

About:

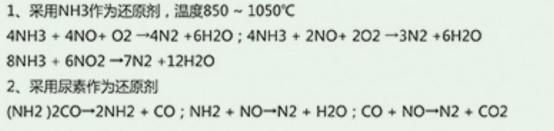

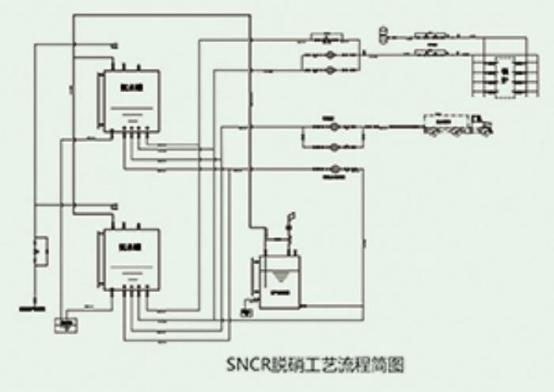

selective non-catalytic reduction (SNCR) refers to reducing nitrogen oxides in flue gas into harmless nitrogen and water by spraying reducing agents in the “temperature window” suitable for denitrification reaction without the action of catalyst. This technology generally uses ammonia, urea or hydrocarbamic acid injection in the furnace as reducing agent to reduce NO. The reducing agent only reacts with NOx in the flue gas, generally does not react with oxygen, and the technology does not use catalysts, so this method is called selective non-catalytic reduction method (SNCR). Since the process does not use a catalyst, it is necessary to add a reducing agent in the high temperature region. The reducing agent is sprayed into the area of the furnace barrier temperature of 850 ~ 1050C, and rapidly thermal decomposition into

NH3, which reacts with NOx in the flue gas to form N2 and water. Reaction principle:

Technical advantage

1, simple process, convenient operation

2, 低成本, low operating cost

3, the process is mature, stable operation

4, reducing agent is easy to purchase, the product is no harm

5, denitration efficiency 30%-75%

Fluegas Denitration process (SCA)

Introduction

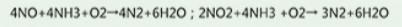

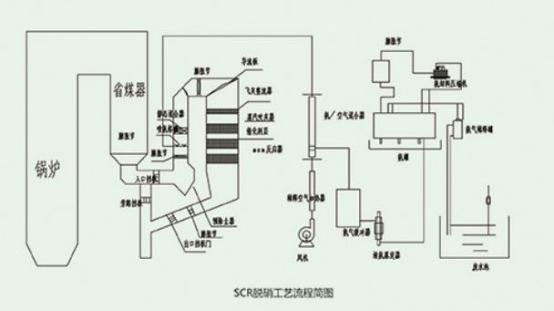

SCR(Selective Catalytic Reduction) is the most widely used flue gas denitrification technology in the world at present, it is basically applied in most power plants in Japan, Europe, the United States and other countries and regions, it has no by-products, no secondary pollution, simple structure of the device, And high removal efficiency (up to more than 90%), reliable operation, easy maintenance and other advantages. Under the action of the catalyst, ammonia is injected into the gas at a temperature of about 280~420C to reduce NOX to N2 and H20, and NH3 and flue gas are uniformly mixed together through a reactor filled with catalysts (such as V205 -TiO2), NOx and NH3 in which the reduction reaction occurs to generate N2 and H20. The catalyst in the reactor is divided into upper and lower layers (generally 1 到 3 layers) placed in an orderly manner.

Reaction principle:

Technical advantage

1, the denitration efficiency is 50%-90%

2, low power consumption, saving operating costs

3, mature technology, stable operation

Flue gas denitration process (SCR+SNCR)

描述:

The SCR+SNCR process, which combines the low construction cost of SNCR with the higher efficiency of SCR, is a combination of denitration and non-catalytic reactions.

Reaction principle:

Technical advantage

1, the cost is low, low operating costs

2, mature technology, stable operation

3, reducing agent is easy to purchase, the product is not harmful

4, denitration efficiency 30% 到 85%

Wet electric dust removal process (WESP) :

描述:

Wet electrostatic precipitator is a kind of new dust removal equipment used to deal with trace dust and micro-particles, mainly used to remove the dust, acid stool, water droplets, aerosol, odor, PM2.5 and other harmful substances in the wet gas, is the ideal equipment for controlling trace atmospheric dust pollution. Wet electrostatic precipitator is usually referred to as WESP, and the basic principle of dust removal of thousand electrostatic precipitator is the same, togo through three stages of charging, collection and ash removal.

Technical advantages

1, with high dust removal efficiency, small pressure loss;

2, simple operation, low energy consumption;

3, no moving parts, no secondary field dust

4, low maintenance costs, short production shutdown period, can work in the flue gas palm temperature below.

Dust collection principle

The wet electrostatic precipitator and the dust collection principle of the thousand electrostatic precipitator are the same, the dust is charged by high voltage corona discharge, and the charged dust reaches the dust collecting plate/tube under the action of electric field force. Thousand type electric dust collector mainly deals with dry gas with very low water content, and wet type electric dust preventer mainly deals with wet gas with high water content and even saturation. There is a big difference between WVESP and DESP in the dust removal method collected on the dust collecting board/pipe. The dry electrostatic precipitator generally uses mechanical vibration or acoustic cleaning to remove the ash on the electrode, while the wet electrostatic precipitator uses regular washing to remove the dust with the flow of the scouring liquid.

To the chimney whitesmoke wet electric fog eliminator

About:

Hebei Guangxing Machinery Co., Ltd. in digesting Germany Lurgi advanced technology at the same time, according to the national conditions of the technology targeted improvement, BH series wet electric dust defog, adapt to wide temperature conditions, no need to reheat the flue gas after treatment, after special process of electric field and electrode structure, can effectively enrich and charge water droplets, Precise capture of ordinary wet electric dust defogging device can not collect ultra-fine droplets, dust, aerosol and a variety of heavy metal pollutants, removal efficiency is high, widely used in metallurgy, 电力, 化学, pharmaceutical, paper making, printing and dyeing and many other industries of tobacco meat whitening and ultra-low emissions. The final discharge of dust and water mist at the chimney outlet can be lower than 5mg/Nm3, which solves the problem of dust bottom discharge and eliminates the problem of flue gas whitening