Round Pipe Belt Conveyor Overview

Tubular belt conveyor “hereinafter referred to as pipe belt machine” is a new type of bulk material conveying equipment developed by our company by absorbing foreign advanced technology. The product is suitable for conveying various bulk materials with a density of 0-25t/m under various complex terrain conditions, and the working environment temperature of ordinary tubular tape is used in the range of -25C to +40C; If special requirements are required, special specifications are used to allow the working environment temperature to reach +160C. The maximum material conveying particle size of the pipe belt machine is 400mm. Typical materials conveyed are: خام, coal coke, limestone, crushed stone, oil shale and sintered mixture. Some very difficult materials such as clay, waste residue, concrete, metal waste residue, fly ash, tailing, bauxite and dust filter can also be conveyed by pipe belt machine. The product can be widely used in electric power, مواد بناء, الصناعة الكيميائية, mining, علم المعادن, wharf, ميناء, فحم, grain and other industries.

Round Pipe Belt Conveyor BASICSTRUCTURE

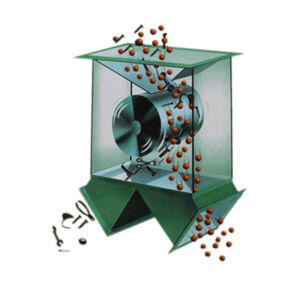

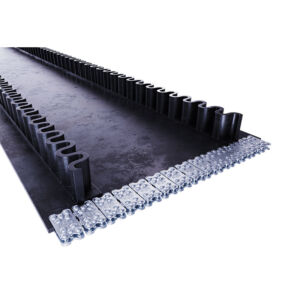

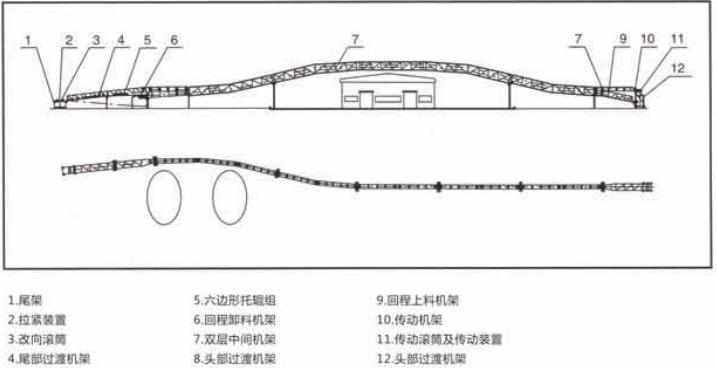

The machine usually uses a hexagonal arrangement of idler groups to force the conveyor belt to roll into a round tube to transport materials. The head, tail, receiving section, discharge section, tensioning device, إلخ. of the pipe belt machine are basically the same as ordinary belt conveyors in structure. After receiving the material in the excessive section of the tail, the conveyor belt is gradually rolled into a round tube for closed conveying of materials, and then gradually unfolds to the head transition section until the material is discharged. The specific structure of the pipe belt machine is shown in Figure 1, and the cross-sectional view of the pipe belt machine is shown in Figure 2.

Round Pipe Belt Conveyor TUBEWITHAMACHINESTRUCTURE

| PRODUCT SPECIFICATIONS AND PARAMETERS Table 1, pipe diameter (bandwidth, breaking area and allowable blockiness corresponding to different pipe diameters) |

|||||||||||

| Pipe diameter(مم) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 850 |

| bandwidth(مم) | 400 | 600 | 780 | 1000 | 1150 | 1300 | 1530 | 1900 | 2250 | 2650 | 3150 |

| Broken area100%(م) | 0.0079 | 0.018 | 0.031 | 0.053 | 0.064 | 0.09 | 0.147 | 0.21 | 0.291 | 0.2789 | 0.5442 |

| Broken area75%(m³) | 0.0059 | 0.013 | 0.023 | 0.04 | 0.048 | 0.068 | 0.11 | 0.157 | 0.218 | 0.2842 | 0.4081 |

| Maximum blockiness(مم) | 30 | 30-50 | 50-70 | 70-90 | 90 -100 |

100 -120 |

120 -150 |

150 -200 |

200 -250 |

250 -300 |

300 -400 |

| Ordinary belt conveying Machine corresponding width(مم) |

300 -400 |

500 -600 |

600 -750 |

750 -900 |

900 -1050 |

1050 -1200 |

1200 -1500 |

1500 -1800 |

1800 -2000 |

2000 -2400 |

|

| 表2,输送能力 | |||||||||||

| 管程tmm)需通 评m | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 850 |

| 0.8 | 17 | 37 | 66 | 118 | 138 | ||||||

| 1.0 | 21 | 47 | 83 | 148 | 173 | 238 | |||||

| 1.25 | 26 | 59 | 104 | 185 | 216 | 297 | 482 | 688 | |||

| 1.6 | 33 | 75 | 132 | 232 | 276 | 380 | 616 | 881 | 1238 | 1616 | 2327 |

| 2.0 | 42 | 94 | 166 | 296 | 346 | 472 | 770 | 1100 | 1548 | 2022 | 2909 |

| 2.5 | 208 | 370 | 432 | 594 | 964 | 1376 | 1935 | 2528 | 3636 | ||

| 3.15 | 460 | 543 | 748 | 1213 | 1734 | 2438 | 3185 | 4581 | |||

| 4.0 | 950 | 1540 | 2200 | 3096 | 4044 | 5818 | |||||

| 5.0 | 1928 | 2750 | 3870 | 5056 | 7272 | ||||||

Round Pipe Belt Conveyor Description

Tubular belt conveyor is a special continuous conveying equipment developed on the basis of ordinary trough belt conveyor. Its conveying path can be arranged with a spatial curve, the conveying inclination angle is large, ومسافة النقل الفردية طويلة في ظل ظروف التضاريس المعقدة, والتي يمكنها التغلب على عيوب ناقل الحزام العادي والقيود المفروضة على نطاق الاستخدام, ويمكن لهيكلها المغلق أيضًا أن يقلل من فقدان المواد أثناء النقل والتلوث البيئي.